Fowler Industrial Plating offers a wide range of metal surface preparation and finishing services designed to enhance the performance, durability, and aesthetic appeal of your components. With extensive experience and a commitment to quality, we provide solutions ranging from glass bead blasting and polishing to precision buffing and chemical deoxidizing. Our services are crucial for optimal coating adhesion, achieving the desired finish, and maintaining the integrity of parts across numerous industries.

Metal Surface Prep and Finishing Services

Glass Beading for Uniform Matte Textures

Glass bead blasting is a non-destructive method used to clean and smooth metal surfaces. This process effectively removes scale, paint, rust, and other contaminants without causing damage or altering the substrate’s dimensions. Glass bead blasting can achieve a uniform, satin-like texture on metals like aluminum and stainless steel, improving both the visual appearance and the surface’s ability to bond with subsequent coatings.

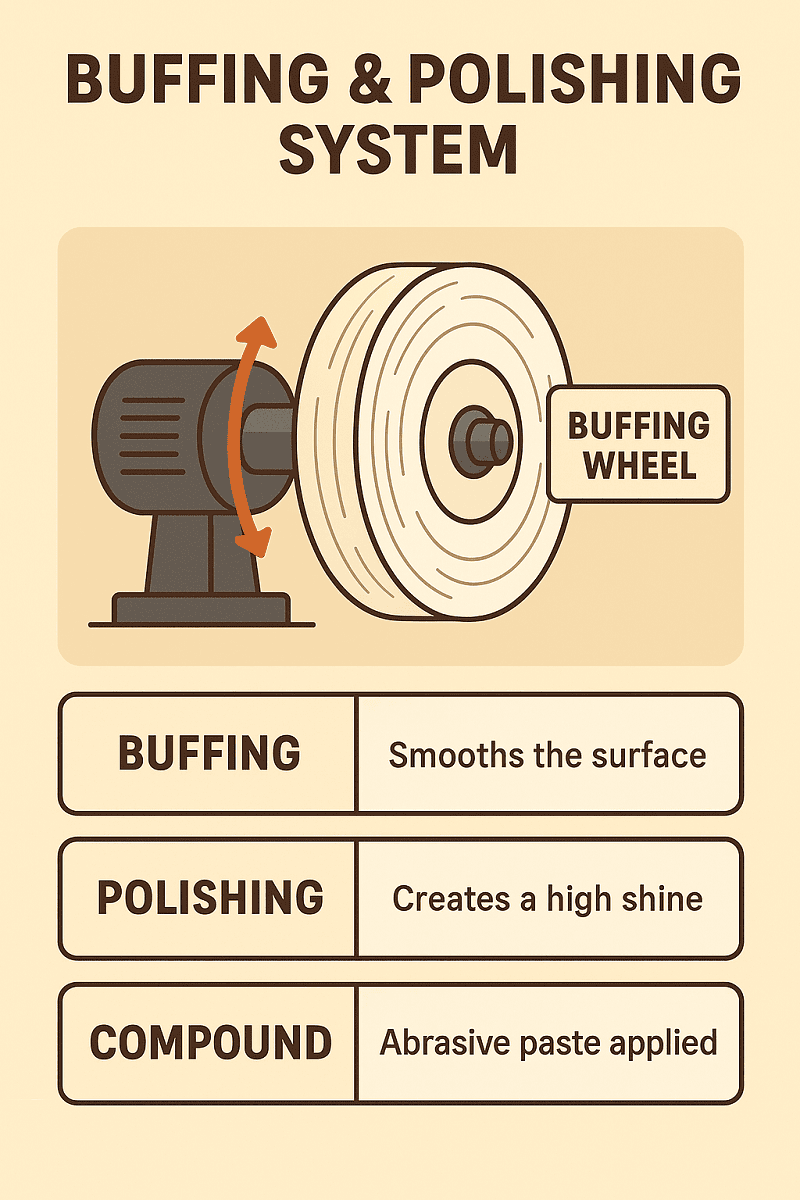

Buffing and Polishing for High Shine Finishes

Buffing and polishing are mechanical processes used to smooth metal surfaces to achieve finishes ranging from matte to mirror-like. Buffing utilizes a soft cloth wheel and fine abrasive compounds to create a high-gloss finish. Polishing is a more aggressive process that uses an abrasive wheel to remove a thin layer of the surface, correcting imperfections and producing a brighter, more polished finish.

Chemical Deoxidation to Remove Oxides

Chemical deoxidizing is a critical pre-treatment process, particularly for aluminum and aluminum alloys. This process removes the naturally occurring oxide layer that can hinder coating adhesion and promote corrosion. It uses chemical solutions that react with and dissolve the oxide layer, which can’t be achieved using standard cleaning methods. By creating a clean, oxide-free surface, chemical deoxidation ensures a strong bond for subsequent coatings and enhances the overall corrosion resistance of the end product.

Why Surface Preparation Is Critical

Proper surface preparation is important for numerous reasons, including:

- Improves plating and coating consistency. Adequate surface preparation is key to achieving consistent and reliable coating and plating results. Removing oxides, contaminants, and surface irregularities creates a clean, uniform substrate that promotes optimal coating adhesion, improves durability, and ensures a high-quality finish.

- Enhances the visual appearance of finished parts. Surface finishing processes like buffing and polishing help to improve the aesthetic appeal of metal components. These processes not only create a smooth, polished surface but also eliminate oxidation and other surface defects that can affect the longevity and appearance of parts.

- Removes heat tint, oxides, and residue. Our surface preparation methods are highly effective in removing oxides, heat tint, and residual contaminants from metal surfaces. This creates a clean substrate that is ready for further processing, such as coating or plating.

Get a Quote for Metal Finishing Services

Fowler Industrial Plating is your trusted source for reliable, high-quality surface preparation and finishing services. We offer a diverse range of capabilities, including stainless steel polishing, steel buffing, and chemical deoxidizing, all designed to improve the appearance and performance of your components.

No matter your requirements, we can deliver quality results you can depend on. Contact us today to learn more about our surface preparation and finishing services.