Fowler Industrial provides surface passivation treatments to modify certain types of metals, including stainless steel, at the molecular level. Stainless steel passivation helps product engineers across numerous industries meet challenging performance and longevity goals. Learn more about our stainless steel surface passivation process, including its key benefits and applications.

What Are the Types of Passivation?

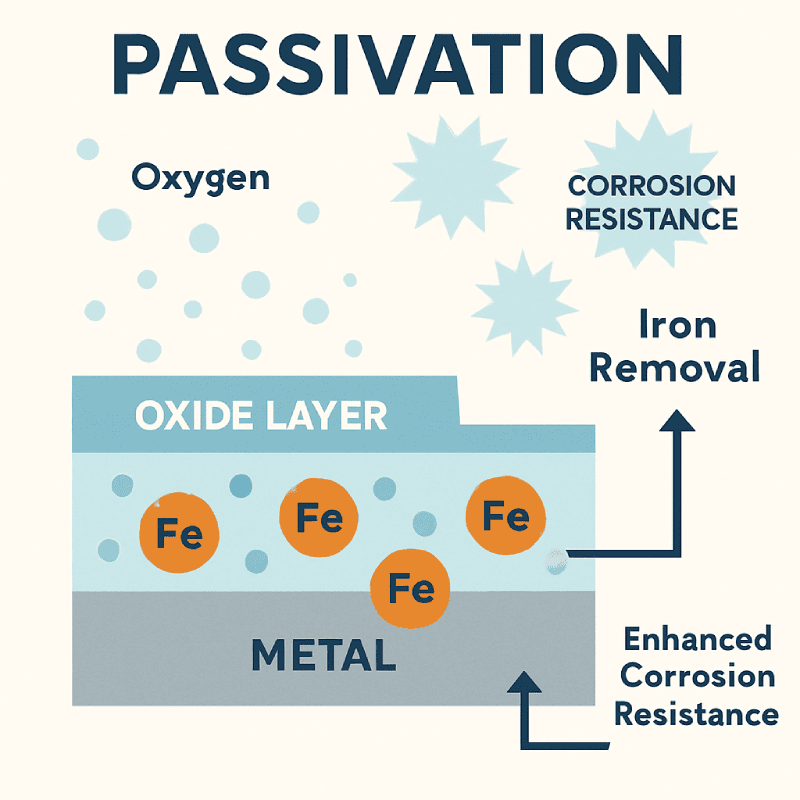

Passivation is a surface treatment method that enhances certain types of metals by altering their chemical composition. It uses an acidic solution that removes surface contaminants and improves corrosion resistance.

There is one main way of passivating metal which meet ASTM A967 and AMS 2700 standards:

- Nitric acid passivation. This is the traditional, chemically intensive passivation method compatible with a broad range of stainless steel alloys and grades.

Both surface passivation methods remove contaminants like free iron, allowing a chromium-rich oxide layer to form on the metal surface. This oxide layer is akin to a barrier that protects the metal from many external sources of corrosion.

Compliance

Our stainless steel passivation services strictly adhere to ASTM A967, ASTM A380, ASTM B600, and AMS 2700 standards, which establish safe, uniform procedures for chemically passivating metal. These standards also outline important benchmarks for quality and performance in specific industrial applications.

Fowler Industrial’s Passivation Process

Pre-Cleaning and Part Inspection

We begin with a thorough cleaning to strip the stainless steel surfaces of grease, oil, and other contaminants. Doing so is critical to improving the effectiveness of the passivation process.

Acid Bath Immersion and Rinse

Our experienced technicians immerse stainless steel parts in a bath under carefully controlled conditions. The acid treatment removes free iron (and any leftover contaminants). Afterward, we rinse any residual acids from the passivated part using deionized water.

Post-Treatment Testing and Validation

The final step is to test each part and verify the effectiveness of the metal passivation process. To maintain optimal product quality, Fowler Industrial specializes in several application-specific testing methods, including:

- Copper sulfate testing

- Salt spray testing

- High humidity exposure

Benefits of Stainless Steel Passivation

Improves Corrosion Resistance

By removing impurities, passivation helps stainless steel resist corrosion from harsh environmental conditions. Surface passivation also helps extend part longevity and improve performance.

Enhances Surface Cleanliness

Passivation eliminates contaminants at the molecular level to enhance cleanliness without damaging the surface. This is important for industries dependent on strict purity and hygiene (e.g., food and pharmaceutical manufacturing).

Extends Component Lifespan

Preventing corrosion while preserving surface integrity significantly improves product lifespan. Using passivated stainless steel parts thus helps maintain performance while reducing maintenance and repair costs.

Request a Passivation Quote Today

Surface passivation is an affordable and effective way to permanently alter and improve the material properties of a variety of metal parts. Stainless steel passivation is particularly useful for industries that rely on stainless steel for its durability, longevity, and/or cleanliness. Fowler Industrial Plating is an ISO 9001:2015 certified company providing high-quality passivation, hard-gold plating, and other plating services for a variety of alloys. Our team has almost 100 years of combined experience in plating and finishing.

To learn more about our state-of-the-art metal passivation services or to request a quote, contact us today.