| Process | Base Metal | Spec Reference |

|---|---|---|

| Electroless Nickel | All | MIL-C-26074 |

| Electroless Nickel-Cobalt | All | MIL-C-26074 |

| Gold Electroplating | All | MIL-G-45204 |

| Black Oxide | Steel | ASTM D769 |

| Black Oxide | Copper | MIL-STD-171 |

| Passivation | Stainless Steel | ASTM A967 |

| Teflon Coating (PTFE) | All | MIL-A-63576 Type II |

| Cleaning, Surface Prep | All | All |

| Glass Beading | All | All |

| Masking & Plugging | All | All |

| Lab Analysis | **** | Hourly |

| Heat Treating (Small parts only) | Steel alloys only | ASTM A389 |

| Aluminum Anodizing, Types II & III, Classes I & II (Sulfuric Acid) | Aluminum, all Alloys |

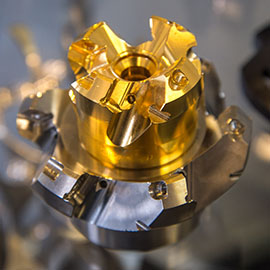

Fowler Industrial Plating introduces a Bronze Electroless Nickel process that offers 800 knoop microhardness and corrosion resistance of up to 740 hours to white rust under 5% salt spray testing. FIP-Bronze E-Nickel coatings can be deposited to any base metal and are available in bright, high gloss finishes as well as semi-bright and dull (matte) finishes. FIP-Bronze E-Nickel is deposited in accordance with MIL-C-26074 and ASTM B733 specifications and is available from .1 mils (0.0001”) to 3 mils (0.003”) thickness.

Fowler Industrial Plating introduces a Black Electroless Nickel process that offers 800 knoop microhardness and corrosion resistance of up to 740 hours to white rust under 5% salt spray testing. FIP-Black E-Nickel coatings can be deposited to any base metal and are available in bright, high gloss finishes as well as semi-bright and dull (matte) finishes. FIP-Black E-Nickel is deposited in accordance with MIL-C-26074 and ASTM B733 specifications and is available from .1 mils (0.0001”) to 3 mils (0.003”) thickness.

Bright, hard-gold electroplating deposits a 99.7% gold / 0.3% cobalt alloy onto the substrate. Many people ask if it is “real gold.” Yes, it is real gold, and boasts a karat value of over 23. Bright, hard-gold is used extensively in the electronics industry (printed circuit boards), as well as the cryogenics industry, among others.

100% SATISFACTION GUARANTEED

At Fowler Industrial Plating, we work to ISO / ASTM and MIL Standards. We guarantee that our work will meet and exceed all specifications; both technically and aesthetically.

Let us know how we can help meet your needs. Our company has many years of experience and we continually strive to be the best at what we do. Thank you for visiting our website and don't hesitate to contact us! We look forward to doing business with you.

Call us now: 423-813-7272

For further questions or concerns please email randy@fowlerindustrial.com or call 423-813-7272